5-axis has gained traction as the top technology for creating complicated pieces with great speed, high-capacity, accuracy and reduction of human error. Prior to 5-axis, these parts required multiple setups, wasting precious time that can cost a lot of money.

Regardless of 5-axis’ successes, certain myths continue to revolve around the 5-axis process. Debunking these myths can not only help you better understand 5-axis machining but also hopefully help your shop run more smoothly and efficiently.

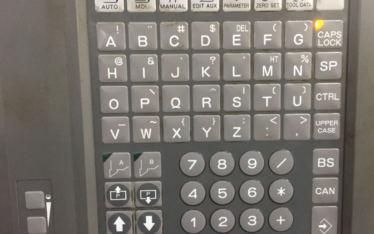

5-AXIS MACHINE CONTROLS ARE TOO COMPLEX

Not all 5-axis machines are created equal; Okuma machines are actually intuitive and easy to use. Our 5-axis machines include our very own OSP P300M controls, which use a standard G code format with menu-driven cycles, and they’re completely customizable through our Okuma app store.

5-AXIS MACHINES ARE TOO EXPENSIVE

When you compare your standard vertical machining center to a 5-axis machine, the numbers can seem high. That’s why it’s important to look at the big picture. If your vertical machine is using special software or parts to achieve five axes or even a 3+2 operation, you’ve already spent the money in add-ons without receiving any of the 5-axis machine benefits (e.g. 5-axis auto-tuning, posture control, etc.) Plus, the return your shop will see with 5-axis heavily outweighs the initial cost.

5-AXIS SOFTWARE CAPABILITIES ARE TOO ADVANCED

It’s much easier to bridge the gap between your system and the 5-axis machine than you think. If you already possess Mastercam, GibbsCam, Autodesk, Espirit, HyperMill, NX or another similar software, your 5-axis machine can directly translate the coding dialect.

5-AXIS REQUIRES TOO MUCH TRAINING

At Okuma, our customer service doesn’t end the minute you purchase a machine. We provide a multitude of resources for your new machine, including 5-axis onsite training, PCNC Master and offsite training. Between our partners, your distributor and our team, we’ll have you settled and making the most of your machine in no time.

5-AXIS INVOLVES SKILLED LABOR

5-axis no longer requires specially trained labor, in fact, it’s the opposite. Our 5-axis machine’s dynamic fixture offset eliminates the need to set the part on the exact center of rotation, giving any employee the opportunity to excel in 5-axis setup. Our machines come as close as possible to the “done in one” mantra, which means there’s a massive reduction of human error.

5-AXIS MACHINES CREATE POSITIONAL INACCURACIES

As with any machine, advancements are happening constantly. Our OSP 5-axis Auto Tuning performs tuning quickly and accurately and compensates up to 11 geometric errors, including volumetric accuracy. Adjustments can be made in just 10 minutes, and it does not require a high level of skill.